Hourihane

Engineering

Engineering Facilities

Turning

Milling

Slotting

Drilling & Boring

Hydraulic Press

Welding & Fabrication

2D and 3D Drawings and Modellings

Materials used:

Mild steel, stainless steel, bronze, cast and nylon.

Engineering: An In-Depth Look

Engineering has always been the cornerstone of modern civilization, shaping our environment and the way we live. This guide explores key engineering processes, including TURNING, MILLING, SLOTTING, DRILLING & BORING, HYDRAULIC PRESS, WELDING & FABRICATION, 2D AND 3D DRAWINGS AND MODELLINGS. We’ll also dive deep into the essential materials that make these processes possible, such as mild steel, stainless steel, bronze, cast, and nylon.

Engineering Processes and Techniques

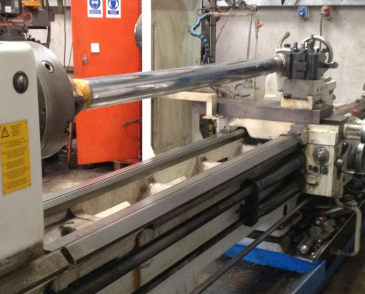

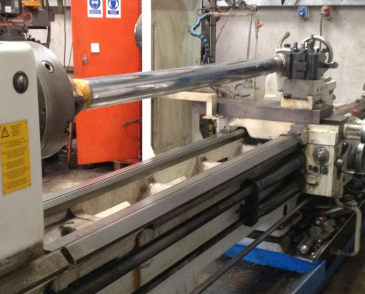

TURNING

Turning is a fundamental machining process where a cutting tool, usually non-rotary, removes material from a rotating workpiece. This action produces cylindrical parts with various shapes, diameters, and sizes. The precision and efficiency of turning are instrumental in producing components for industries ranging from automotive to aerospace.

MILLING

Milling, unlike turning, involves a rotary cutting tool moving against a stationary workpiece. This process can create a wide range of shapes and designs, thanks to its versatility. Modern CNC (Computer Numerical Control) milling machines have revolutionized industries by achieving impeccable precision.

SLOTTING

Slotting or shaping is all about cutting grooves, slots, and keyways. This operation uses a machine similar to a milling machine, but instead of a rotating cutter, it has a linear reciprocating tool. It’s a go-to process for making internal shapes and forms.

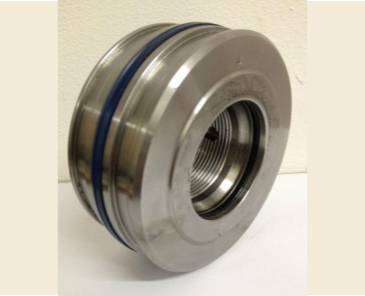

DRILLING & BORING

Drilling and boring are essential for creating holes. While drilling commences the hole, boring refines it to perfect diameters and finishes. These processes play a vital role in industries where holes are required for bolts, screws, or precision fittings.

HYDRAULIC PRESS

Hydraulic presses utilize fluid pressure to generate a compressive force. They’re crucial for tasks such as metal forming, moulding, forging, clinching, and laminating. This powerful tool has transformed manufacturing lines worldwide.

WELDING & FABRICATION

Welding is all about joining materials together, predominantly metals. With a blend of heat and pressure, welding ensures a strong bond between materials. Fabrication, on the other hand, involves constructing products by manipulating raw materials, a cornerstone of industrial manufacturing.

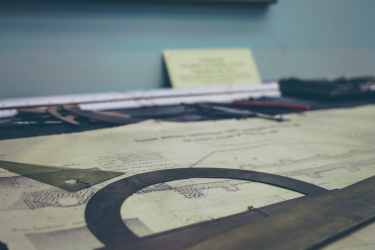

2D AND 3D DRAWINGS AND MODELLINGS

Drawing and modelling serve as the blueprint for engineering processes. 2D drawings give a flat representation, while 3D modelling provides a holistic view of the design, enabling engineers to visualize, test, and rectify designs before the actual production.

MATERIAL MATTERS IN ENGINEERING

Mild Steel

Mild steel, often termed as low carbon steel, is renowned for its malleability and weldability. It’s a staple in construction, automobile, and even in the production of nails and chains.

STAINLESS STEEL

Boasting corrosion resistance, stainless steel has applications that require durability and longevity. From kitchen sinks to surgical instruments, its presence is undeniable.

BRONZE

Bronze, an alloy of copper and tin, has historical significance and modern relevance. It’s preferred for its corrosion resistance and aesthetic appeal, making it a favorite for sculptures and medals.

CAST

The casting process involves pouring molten metal into a mould. This allows for intricate designs and shapes, pivotal in the automotive and aerospace sectors.

NYLON

Nylon, a type of polymer, isn’t a metal but holds significant importance in engineering. Its strength, elasticity, and resistance to wear make it ideal for gears, bushings, and countless other components.

CONCLUSION

Engineering is a vast and intricate field, encompassing a plethora of processes and materials that have shaped our modern world. From the precision of turning and milling to the strength of materials like stainless steel and nylon, engineering continues to be the backbone of innovation. Whether you’re a budding engineer or someone intrigued by the magic of machines, understanding these processes deepens your appreciation for the marvels of engineering.